We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Sigma Bespoke Multi-Purpose Safety Pallet Gate - Mezzbarriers - By Brand

Sigma Bespoke Multi-Purpose Safety Pallet Gate

Key Features

- Meets HSE and Safety professionals requirements for site safety. - Conformance with BS EN ISO 14122-3:2016 - High loads up to 2250 mm within low headroom

- Bespoke versions with inside width up to 3.0 metres x inside depth up to 4.0 metres - Plus additional features

- Multi-purpose design - For mezzanines, process platforms, doorways and more - Easy to install with installation and operating instructions provided

- Separates personnel from moving loads and falls from unprotected edge. - Operates without protruding over the floor edge.

- Galvanised or Safety yellow thermoplastic coated tube - All parts are replaceable - CE marked

Sigma Bespoke Multi-Purpose Safety Pallet Gate

This new concept pallet gate has features designed to solve specific problems not addressed by other models.

What’s so special?

Conforms to BS EN ISO 14122-3:2016 Mezzanine Gates

It does not protrude over the floor's edge. No overhead bars when loading. Less risk of damage during the loading operation.

Fitted with 100 mm high Aluminium kick plate

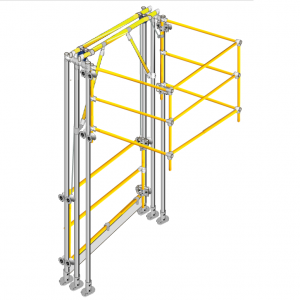

When the operator pulls down the inner gate, the mechanisms incorporated in the side frames automatically pivot up the two edge gates to the vertical position on either side of the opening. See the video on this page.

When used with standard pallets, the side frames can be reduced for space-saving, allowing good access to a pallet on three sides. This model can also be used with a vacuum-handling crane for unloading bags, sacks, etc. Read more about special applications below. With the inner gate raised this model offers more usable floor space for confined areas.

The design can be adapted for use with inward-opening doors or roller shutters and is especially useful for use with hoists on low runway beams. When the gates are fitted to deeper side frames, the inner gate folds up, under the runway, behind the load when landed.

The construction combines our tried and tested standard tube, and component construction merged with specially designed pivot joints and tube rotators.

Finish

- All galvanised

- Safety yellow thermoplastic (Warm to touch) coated tube and galvanised components

- Optional Aluminium floor/edge protection plate 1250 mm wide x 1150 mm deep plus 100 mm fold down. 3 mm checker plate (Undrilled). Recommended for wooden floors. Buy two for wider gates.

Special applications

In addition to normal forklift loading, this model can be used with hoists, in doorways, and with vacuum handling cranes - See notes below for the Sigma model is offered to bespoke requirements -

|

Model |

A Handrail height mm |

B Inside/outside |

C Inside/outside |

D Overall depth open mm |

E Maximum height of the inner gate mm |

F Maximum |

G |

|

Sigma |

1100 |

Up to 3000❶ / + 800 ❷ |

Minimum 500mm |

C + E |

Up to 2400 |

Up to 2250 |

Varies relative |

Full specifications are shown in the Sigma Cut Sheet download PDF

*Dimensions are approximate only. Due to differences in the tube clamps and the assembly process, the actual

dimensions may vary. Any critical dimensions, such as hole fixing centres, should be determined when the product

is actually on your site. We reserve the right to change the design without notice

|

❶ Bespoke inside width - We recommend that you allow at least 200 mm load clearance for the inside gate ❷ Overall width, including side frames. e.g. 2000 mm gate inside width = 2800 mm gap required (Overall width) Standard Installation requires 8 x M12 Bolts/Anchors (Not provided) |

Special notes: (You can tell us about any special features or extras you require in the additional information box.

The depth of the gate will vary according to the height and depth of the load to be cleared by the fold down the inner gate and the length of the side frames. Overall height varies according to the length of side frames.

Usually, there is a trade-off between space-saving and load clearance requirements. The longer we can make the side frames the lower the fold-down inner gate can be to clear the load.

For minimum height with a fold-down gate behind load depth, we recommend that you allow at least 100mm load clearance on inside height to use a pallet truck to remove the load..

Information we need:

The maximum size pallet(s) or load W x D X H. We will need to know the unrestricted headroom above the gate location. The available gap for the gate to operate within. The available operating depth and how the gate will be loaded e.g. forklift or overhead hoist.

.Loading by hoist

|

If you intend to use the gate for loading with a hoist with or without doors, the side frame will need to be of sufficient length for the inner gate to fold back up behind the load. The inner gate must be closed (Vertical) to access the load. The load has to be landed to disconnect from the hoist within the landing safety area. Landing onto a suitable trolley or pallet truck allows a non-wheeled load to be moved further in. We will need the height to the underside of the runway beam. Please download Sigma Hoist Loading Questionnaire PDF |

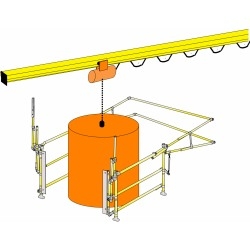

Unloading load/pallet with a hoist

|

For applications where the palletized load is to be unloaded e.g. vacuum hoist for sacks. The side frames can be made with minimum depth, and the inner gate can be raked forward in the folded position when shut. This allows the hoist to swing over the entire pallet. If you can give us the precise dimensions, we can calculate the optimum dimensions required to clear the load. Note: We also supply the Vaculex sack lifter shown in the photo. |

Doorway applications

This model can also be used with inward opening doors or roller shutter doors (See case study for roller shutter opening. If the door has a deep ledge or external dock, it may be possible to install the gate totally outboard of the door. The inner gate can be folded down when the door is opened. We will require the proposed hole cross centres and the thickness of the wall to finalise the arrangement. The outer or edge gates have a kick plate that must land on a ledge. If no ledge exists, you must bolt a door-width bracket to the wall under the outer face door sill. This ISO standard is required to prevent items from falling through the gap between the door sill and the kick plate. |

Component Specification

Mezzbarriers tube clamps are made from malleable cast iron. Manufactured in conformance with BS EN 1562:1997, a dependable and well-proven material for this product type. The fittings are then hot-dipped galvanised to BS EN ISO 1461:1999 to produce a durable corrosion-resistant finished surface for extended life. Grub screws are stainless steel. Specially fabricated components are zinc sprayed as standard.

How to get a quote

Once you have all the dimensions, use our easy online step-by-step quotation request form above to tell us about your application. It may be useful to attach a photo or sketch with the form.

Tip: If you have more than one photo or sketch, you could import them into a Word document and then save or print as a PDF to send.

We have successfully supplied safety gates all around the UK and as far afield as Canada and Australia without ever visiting the worksite. Our component construction gate system is very simple to install, and your employees will find it easy to use and will feel more secure.

Don't forget we're here to help you through the process by phone: 0161 223 1990 or by email: mezzbarriers@dale-lifting.co.uk.

| Frequently asked questions for pallet gates |

|---|